- Last time the condenser was not leak-tight – we fixed it

- We implemented 2 valves to be able to operate under pressure

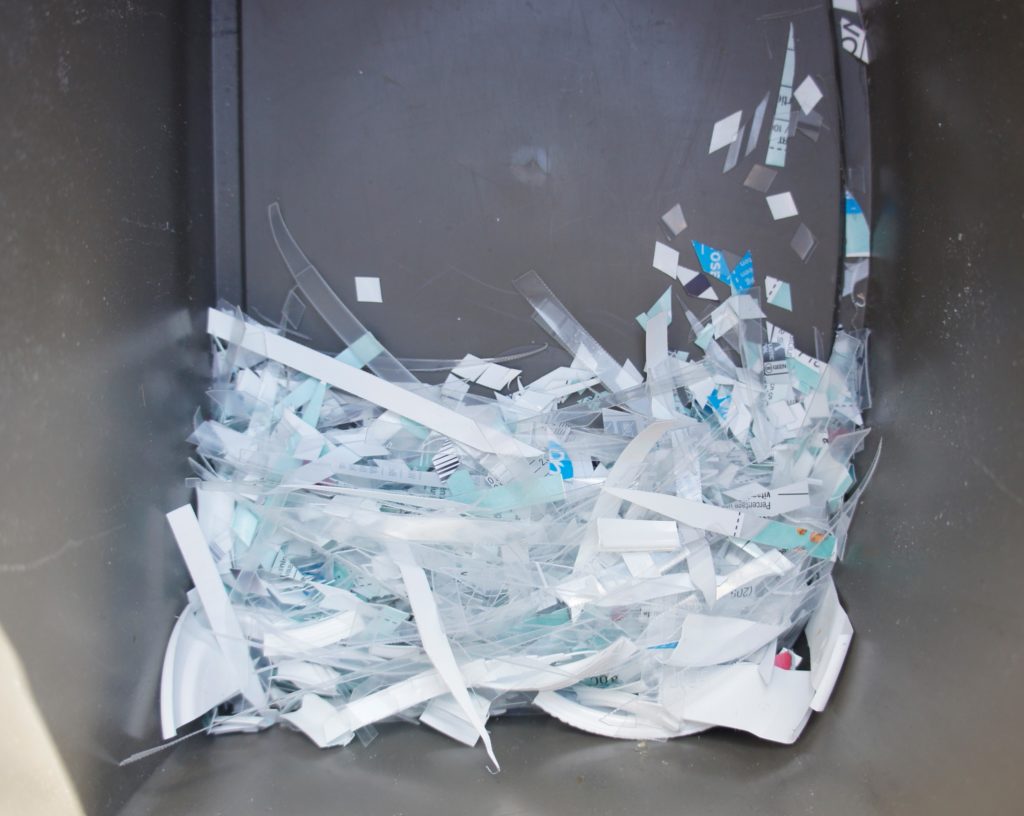

- We retooled a paper shredder for …plastic

The last runs were rather successful. We already obtained some oil. But also some green residual plastic remained in the reactor.

We also noticed that the condenser was leaking, because we could light the gas escaping the connectors. To fix this, we first had to find a way of leak-testing. We connected a bike pump to the tubing, just sticking it into the rubber sealing and applied pressure. To visualize the leaks we sprayed the connections with a water/dish soap mixture.

The reactor part did not show any leaks and also retained pressure, when closed off with a valve for at least half an hour. We fixed the leaks on the condenser with an old bicycle tube.

We also added a valves between the reactor and the condenser, so that we could built up some pressure.

This way, we were able to produce quite a powerful flame from the pyrolysis gas, which could potentially be used to heat the reactor in the future. The oil product produced, however, was quite dark and contained a lot of waxy fractions (see bottom of page). This might have been either, because of the high pressure applied or because of the high temperature used for the pyrolysis. We do not have a temperature sensor inside the reactor yet, but the outside of the reactor was glowing, suggesting an outside temperature well above 1000 C.

The resulting product: