In our last trials, we could already observe the significant influence of pressure and temperature on the types of products produced during pyrolysis of PP. Now, we also investigated the effect of residence time by only allowing certain products to evolve from the reaction.

For the previous trials, we had used 1/8 inch Swagelok tubing and even without using a valve, we observed a pressure buildup up to the point that the reactor started leaking. The buildup occurred due to a clogging of the reactor outlet tubing, which is rather narrow and has a comparatively high external surface area causing it to cool down fast and condense waxes down to their solid state. This is potentially dangerous and influences the reaction. Therefore, we moved to 1/4 inch tubing.

1st version with short outlet and short residence time leading to a very waxy product.

Products obtained with a short (left) and longer (right) residence time.

2nd version with an extended outlet letting waxy products condense and flow back into the reactor, where they are further cracked.

With this alteration, however, we only obtained very waxy, milky colored products. To investigate, whether lower boiling products could be increased by prolonging the residence time in the reactor, we were inspired by TinyHouse and Offgrid Resources, using a long vertical outlet to let high boiling products condense and flow back into the reactor until they are volatile enough to escape. For that, we inserted an almost vertical segment in our outlet tubing with a total length of about 27 cm.

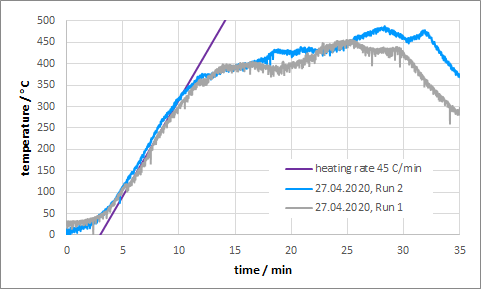

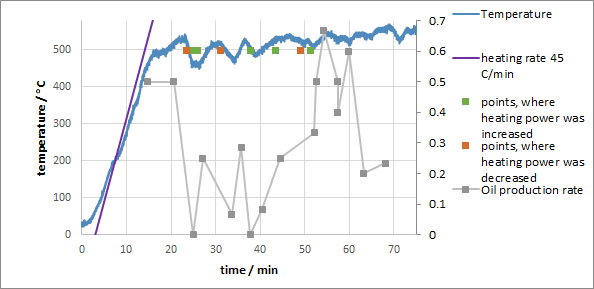

This immediately lead to the formation of an entirely liquid, amber-colored product. The total reaction time increased from about 30-35 min for wax production (Figure 1) to 75 min (Figure 2) using 24 g of plastic. 16 g of liquid product were obtained starting with 24 g of white PP from yogurt cups, while 20 g of waxes had been produced. The first liquid was observed at around 490 °C. Without reducing the heat, the temperature does not increase further at that point, likely because of the endothermicity of the reaction. After about 4 min, the temperature starts to slowly increase again.

The flow of products is not very continuous, which is due to fluctuations in the reactor temperatures and thus also the temperature of the outlet tubing where the products condense. The temperature of the outlet tubing is highly dependent on the evolution of products, as they carry heat with them and warm up the tube upon condensing. The colder the tube, the less products evolve. Thus we would like to work on a way to control the temperature of the outlet tubing. This will help us choose the most suitable length and temperature for the outlet tubing to control the boiling point range of the products.